Technology

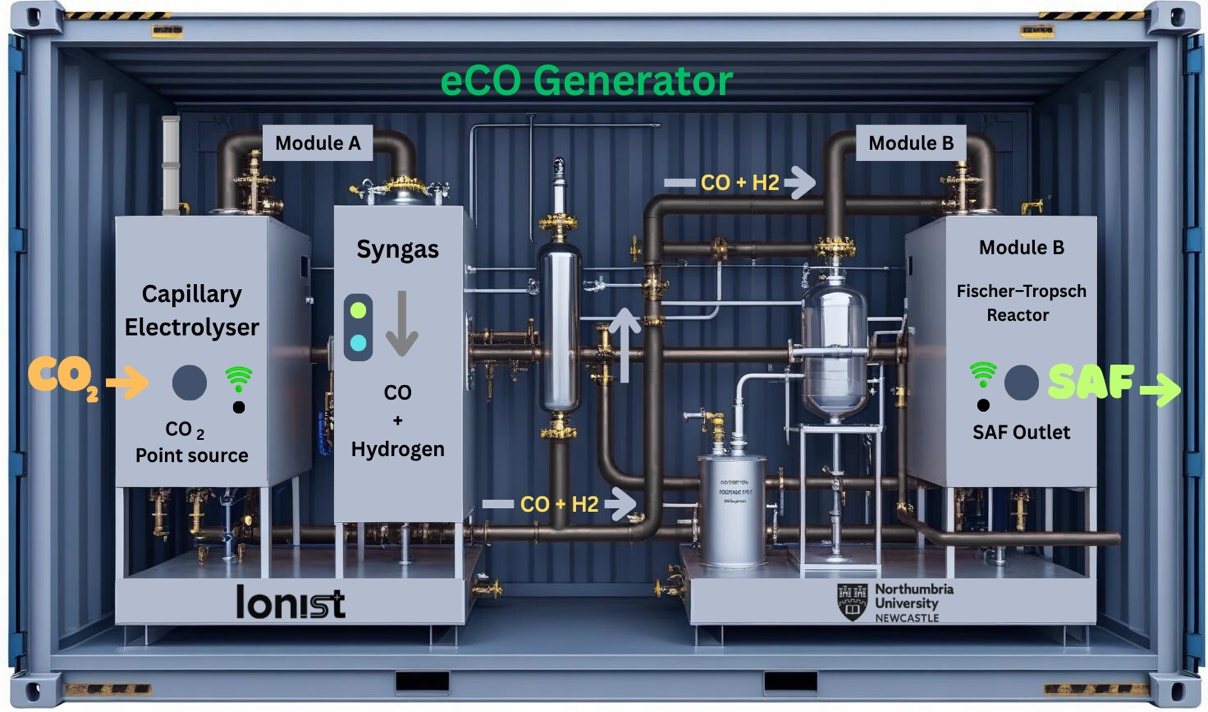

eCOGEN™

A membrane-free capillary electrolyser, running at low temperatures (40–60 °C), converts captured CO₂ into CO with renewable electricity. Compact, modular, and scalable, this unit delivers syngas for downstream fuel synthesis.

eCOSAF™

Our low-pressure Fischer–Tropsch reactor combines CO and renewable hydrogen to produce ASTM-grade SAF (C₈–C₁₆ hydrocarbons). The plug-and-play 20 ft ISO unit is designed for on-site deployment at SME and industrial facilities.

Key Advantages

Modular

Deployable at small, medium, and large scales.

Affordable

Low CAPEX , Early payback.

Efficient

Low-temperature, low-maintenance, membrane-free design.

High Impact

Up to 90% lifecycle CO₂ reduction.

Why IONIST?

- Drop-In Ready SAF compatible with existing engines and infrastructure.

- Circular Approach Turning waste CO₂ into valuable e-fuels.

- Modular Design Flexible units for SMEs to global hubs.

- UK-Based Innovation Delivering green jobs and technology leadership from Newcastle.

- Sustainable Impact A pathway to scale net-zero aviation without competing for land or food.